TECHNOLOGY

Elevn Racing takes a lot into consideration when designing a new product:

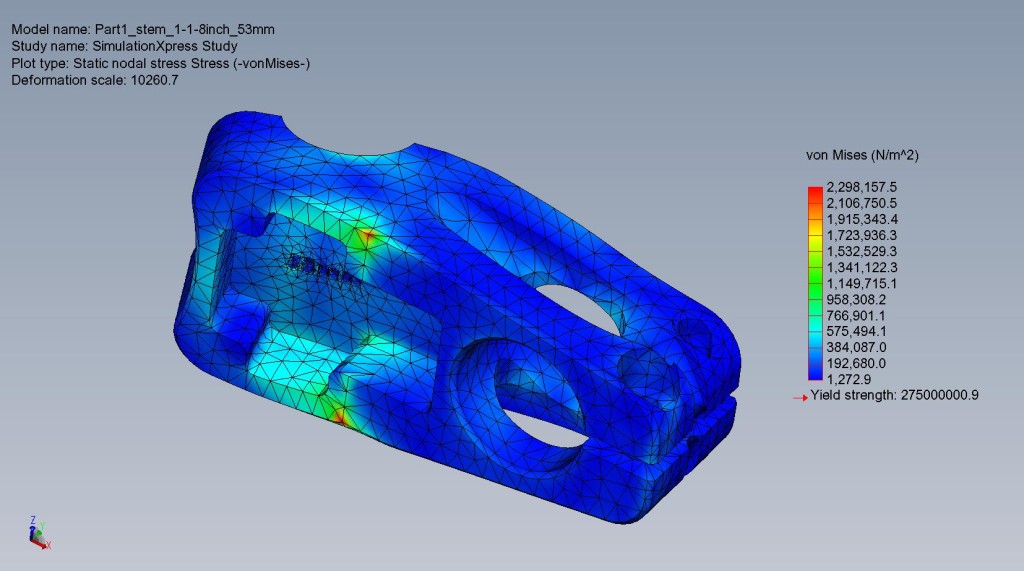

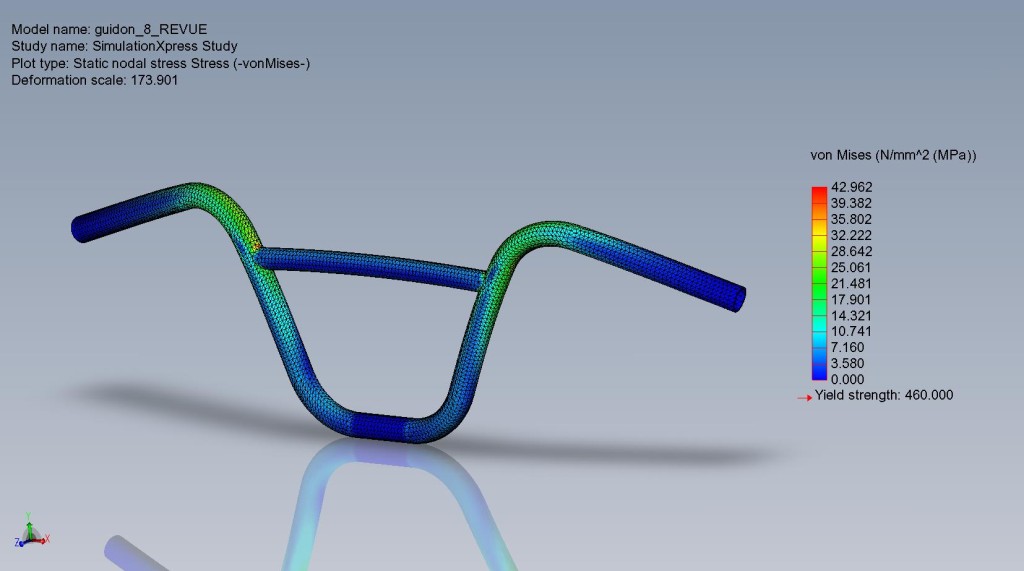

The need, products efficiency, how to safely reduce weight without affecting the overall strength, straight forward design, and many other ideas.

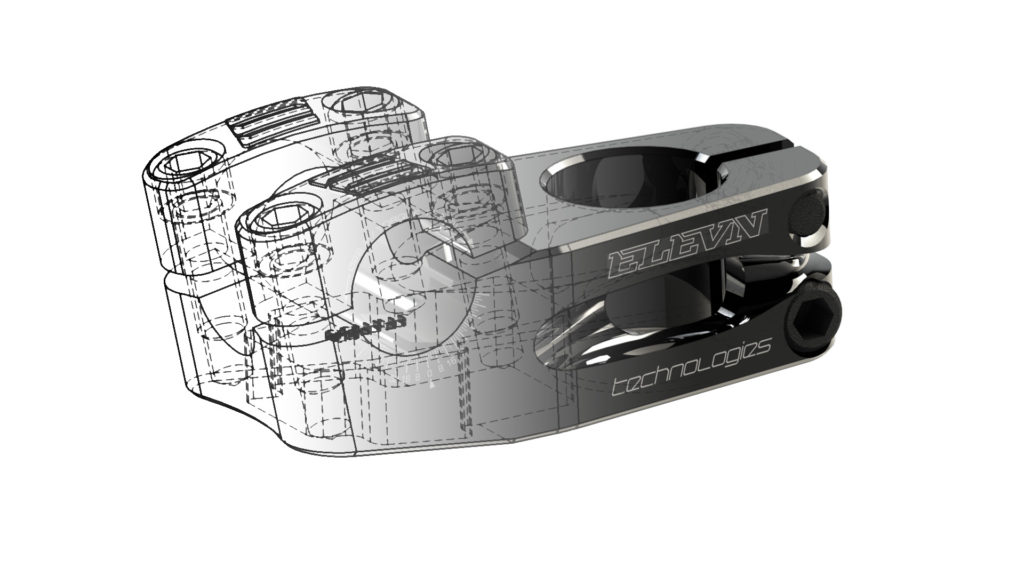

When starting a new design for a product, we spend a lot time in the office discussing the idea and how it can help our pro riders go faster on the track and how we can also offer that to all the BMX racers all over the world. From there its time to sketch out a design, take it to our CAD team to get it designed properly, so we can then talk to our manufactures and suppliers to work on samples.

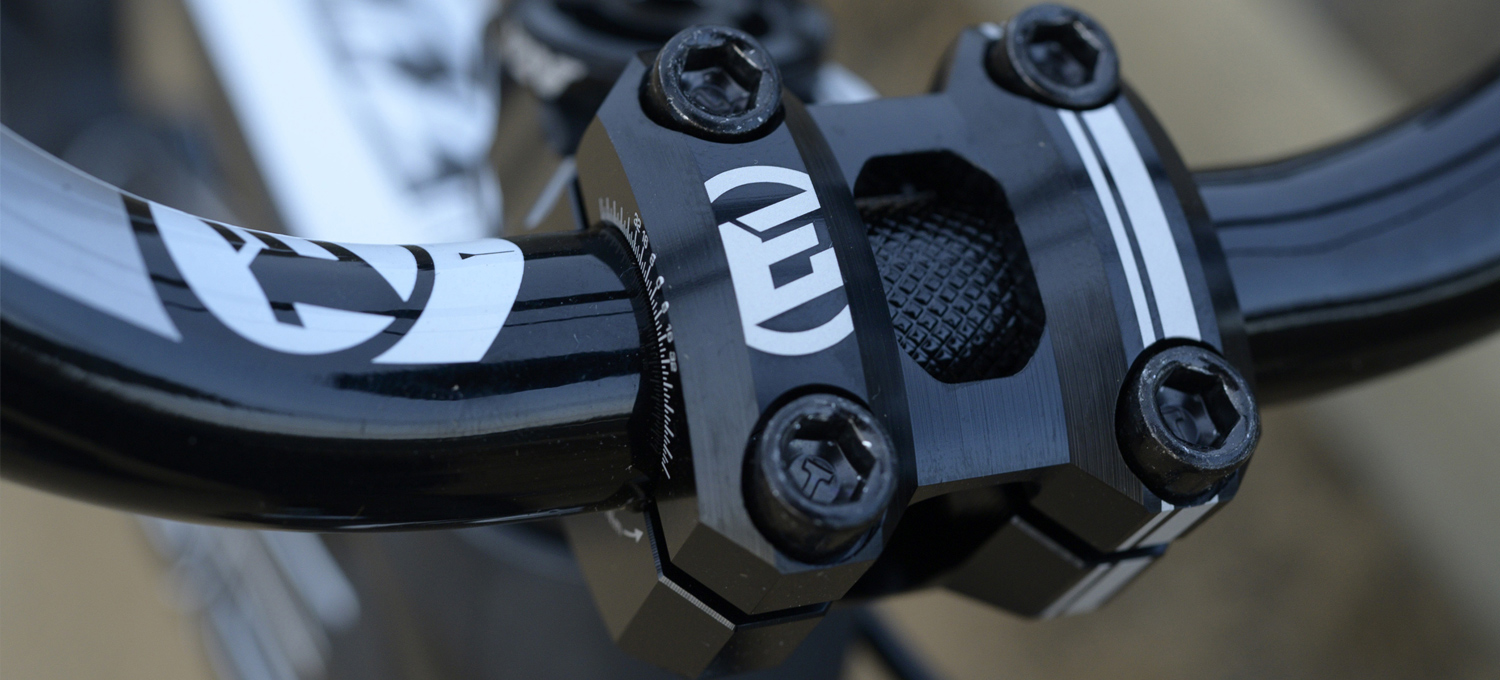

Then its time to visit the manufactures to compare the quality, cost and design of products. It is very important for us to work closely with suppliers to know exactly what is going into the products and ensure that they are being produced ethically, using the most suitable raw materials.

Visiting suppliers entail reviewing the particular product in detail : examining its specifications, looking at Metalology test results, reviewing any issues or concerns and conducting a compliance audit. After a product passes all of these tests, its time for a rider to get on track and test it.

Back at the office, our work usually involves administration tasks such as sampling products, creating new packaging artwork, monitoring and following up any rider comments and complaints and attending internal meetings.